Hers.

Question: what’s more suspenseful than a Game of Thrones finale?

Answer: Our barn door project.

I know we’ve left you in the dark for a bit (ok, maybe an eternity) but we’re finally back to log details for how to create the most cost efficient barn door hardware. I promise it was worth the wait.

So, where were we? Oh, right. Our laundry room looked like this.

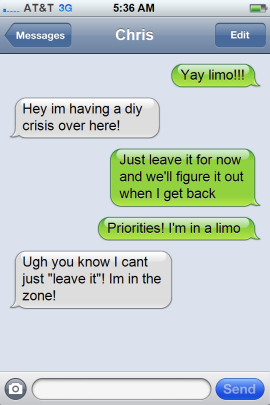

And then we installed a new washer and dryer. The new washer stuck out further than the old one thus blocking the door from being open all the way. Julie goes out of town. Chris goes on a door rampage and rips it out so we’re left doorless.

Julie returns home to find said doorless laundry room. Julie freaks out (just a little) and goes on her own rampage to find a solution.

Enter, the barn door. *Cue the angelic music. The barn door search is on. We soon discover the high prices authentic barn doors are fetching. The search is off.

But then, an idea struck. We could BUILD a door and by “we” I mean my very talented husband… with some lots of coaxing (and beer).

Voilah, instant barn door (sort of). Read our DIY guide for the door here.

Now that you’re caught up, let’s finally let you in on the secret of our super affordable barn door hardware.

Not sure why we were surprised after the shocking realization of the outrageous prices of barn doors, but we soon found ourselves in the same dilemma with the hardware. The going rate for barn door hardware is the equivalent of several pairs of nice, new shoes and I had to somehow justify the new pair of boots that snuck into my shopping cart. We needed an alternative solution especially since I seem to be cursed with expensive taste.

Seriously, every hardware inspiration I pinned on Pinterest seemed to be the most expensive. Lucky me. I was gravitating towards the chunkier hardware with large pulleys that made a big statement. Don’t these make you swoon?

Source: A Tree Lined Street

I found the two below similar options but the price wasn’t exactly on point.

Source: Real Sliding Hardware, $353

Source: Rustica Hardware, starting at $272

So, I turned to Chris and issued a new challenge- recreating the look of this hardware for a fraction of the price. Which, I’m pretty sure his male brain instantly translated into “project = cutting metal = sparks flying everywhere = awesome” because I haven’t heard him agree to a project that quickly… ever.

His.

Now, where were we?

Ah. Yes. Hardware.

But first things first: I had to shrink an entrance.

The door we built wasn’t going to be wide enough to fully close, i.e. a gap would always show. Why did we do such a silly thing? Because a door any wider than the one we built wouldn’t have been able to open all the way before hitting the trim for the entrance to the kitchen. So we actually put up more wood around the doorway so we could use a smaller door which, ironically, meant that we had an effectively larger doorway. What?

Anyway, I first had to removed the door stop pieces from the door frame. A lot of people don’t realize these are just wood pieces nailed onto the door frame, so eliminating a door is actually really easy, and all you need is a hammer and chisel. And sandpaper. And maybe putty. And paint.

Next, I pulled the trim off the outside:

See? Now it’s just a flat frame.

But this still didn’t solve the problem entirely, as I had to reduce the width of the doorway. My solution was to use regular 2×6 lumber. The only problem was that the 2×6 was actually too wide, so I had to rip it down to be the same width as the thickness of the frame.

Recognize that table saw, Pop?

If you’re like Julie and just rely on the pictures to figure out what the heck I’m talking about, behold: a narrower doorway.

Oh and while I was nailing up one side of the trim, the other side I was about to install fell and broke a picture frame. Don’t tell Julie.

So now I could work on hanging the door. Which would require hardware.

After looking at various hardware configurations, I was beginning to get frustrated. There’s really nothing I could find that I could easily modify into barn door hardware, and I was beginning to think we’d have to suck it up and just buy something.

But then I realized something: there’s nothing complex about barn door hardware. There are no complicated linkages, special fittings, or tight tolerances. It’s just brackets and pulleys. And they’re not even fancy brackets. So I figured if I could find the right raw materials, there wasn’t any reason I couldn’t just make my own.

After pondering the configuration, I arrived at the conclusion that apart from fasteners, I’d only need two things, metal flat stock and pulleys. Now all I had to do was design, measure, cut, support, fasten, paint, and mount everything.

I decided the easy part was going to be the track. It didn’t need to be anything more than a straight piece of flat stock, but the problem was that it needed to be over 60″ long and most hardware stores only sell flat stock in 36″ lengths. Fortunately, though, there’s a small “oddity” hardware store around the corner from us, and they had exactly what I needed (I did get a 36″ piece from Home Depot for the brackets, though).

I suppose I should clarify what I’m talking about. “Flat stock” is basically a flat steel rod. For this application, I selected 1.5″ x .125″ (that’s 1/8…) mild steel. I chose this size because it would be thick enough to make a good track and wide enough to run bolts through. I went with mild steel over stainless steel because it’s cheaper, more malleable, easier to cut, lighter, and since I’d be painting it and it would always be indoors, corrosion won’t be an issue. A tip, though: wear gloves when handling carbon steel. It will get on you.

I now had my track piece, but it was too long. So I cut it using my miter saw with a metal-cutting blade. Apparently I’m also available for plumbing work:

The next order of business would be to get it mounted up. Now, since this thing would be supporting the whole door all by its lonesome, it would have to be mounted to the studs in the wall. I figured out where all the studs where and then drilled holes accordingly through the metal.

Next, I mounted a 1×6 that would double as the top trim of the door frame as well as a bracket of sorts for the track. To ensure it would support everything, I made sure to mount it to the existing door frame as well as the studs.

The real trick here was how to mount the track to the board, but also still away from the board. I found some steel bushings at Home Depot that worked perfectly, so I selected some that were big enough to fit around the lag bolts I was using, and long enough to hold the door away from the wall.

And now for the obligatory “Greg Test” (coined after my uncle who the family always made stand on hand-built items by my Grandpa to make sure they wouldn’t crumble):

You know what they say, if it’s strong enough for pull-ups, it’s strong enough for a door.

OK, so now I had a door and something to hang it on… but never the twain shall meet. Yet.

The brackets were a bit trickier, as they’d require more thought. Basically, you can make your door whatever height you want and hang the track however high you want, but it’s up to the brackets to make up the difference.

Of course, this required turning steel flats into… well, I guess they’re basically hooks. But there was still a minor problem: I had a brilliant solution for the brackets, but I really had no clue what I was going to do for rollers. I pondered many solutions with limited success. I thought about porch screen rollers but figured they’re be too weak. I considered A/C pulleys but figured they’d be too bulky. Heck, I almost went with drive belt rollers but they were too expensive.

Then, as if by some twist of fate, I was met with a barn door miracle: https://www.grainger.com/product/AMERICAN-GARAGE-DOOR-Cable-Pulley-5MVF4?functionCode=P2IDP2PCP. They’re technically cable pulleys for a garage door, but they were the perfect size and material for what I needed, with just the right diameter, groove, and even a look Julie liked. And for $7 for the pair, there was no way I could go wrong.

So now that I had all the pieces, I could get to work. After debating multiple designs, I decided that I didn’t want to mess with a ton of metalwork, so I went with a simple hook style, basically an upside-down “J”. The first calculation I needed to know was how far away from the track the pulley needed to be, as this would determine the diameter of the curve. The track was 1.5″ away from the wall, but I actually wanted to door as close to the wall as possible, but also wanted it to hang straight down. After measuring the thickness of the door, I decided it needed to be set back another inch from the track, putting it at 0.5″ away from the wall. And since the bracket would be mounted on the front of the door, I went with a 2″ diameter curve so that when the pulley was in the middle of the arc of the bracket, there would be 1″ of door behind it.

So, how do you measure a 2″ curve when bending steel? Easy. Just bend it around something you know it 2″, like an iron pipe nipple:

I should note here that the reason I’m wearing welding gloves is because I tried heating it up with a propane torch so it would bend easier. It didn’t work. MAPP gas might get hot enough to make it nice and bendy but at the time all I had was propane, and it just wasn’t hot enough. So I had to use vise-grips, a hammer, and some good ole-fashioned elbow grease to shape it around the pipe.

Almost there…

Once I got it all bent up, I needed to drill holes for the bolt that would act as the “axle” for the rollers. To do this, I just set everything up on some saw horses, measured where I wanted the hole, and drilled through both sides at once to ensure they were even.

Once all the pieces were made, I just trimmed them down to even lengths and then primed and painted them in our typical oil-rubbed bronze.

So now that everything was bent, drilled, trimmed, and painted, it was just a matter of mounting everything up in the proper dimensions, which is really just measuring and doing some basic math.

The final order of business was the trim. Remember where I tore the door trim off? Well, I replaced it with some simple 1×6 pieces that I stained to match the door. It’s the same wood that I used for the track support, so utilizing it as door trim gives form to a critical functional piece.

Materials

- Flat stock- 1.5″x1/8″ mild steel: approximately $20

- Stainless steel bushings: $5

- Lag bolts and washers: $10

- Pulleys: $7

- 1×6 Lumber (for track support): $3

- White Primer: $3

- Oil Rubbed Bronze Spray Paint: $6

- Door Handle: $1

Total hardware cost: $55, give or take. With LOTS of extra bolts!

And, finally, the finished product!:

After.

And again, here’s what the whole enchilada looks like…