Hers.

And it’s name is: our pantry door. Chris and I are coming to find that we have bad door luck. I don’t know what kind of bad door karma we picked up over the years… perhaps from my younger self slamming too many of them in teenage angst or Chris graffiti-ing his college dorm door with Irish drinking phases (he argues that his dorm was getting demolished after that semester anyway so why not pay tribute to our home land of paleness and potatoes). Whatever it was, the door species has an enemy number one and it is us.

If you remember, our epic battle with doors began with our patio door. After a year of living with a chewed up door from the previous owner’s dog, we finally bought a new door to replace it. Turns out, the door didn’t fit. A father-in-law, many colorful exclamations, and a full weekend later, the matter was finally resolved. Read more in our post about it here.

Well, the evil door realm went dormant for a few years but, alas, it returned… with a vengeance.

But, let me start at the beginning.

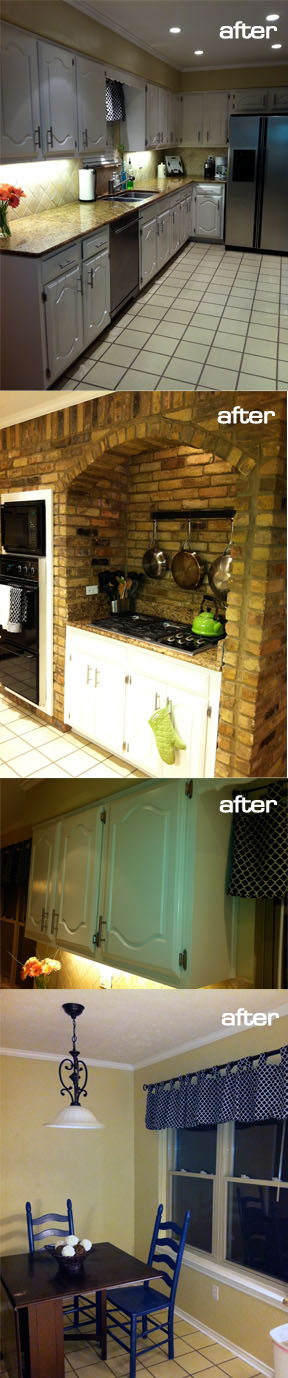

You may remember our pantry renovation where we turned this disorganized, non-functional mess…

Into this super functional, beautiful being (read more on the transformation here).

We decided to replace the old pantry door with a new one that matched the rest of the new doors we’ve been installing throughout the house.

All done, right? Wrong. So very very wrong.

His.

I. (expletive deleted). Hate. Doors. I mean, I really hate them. We live in North Texas, a region notorious for unstable soil. What this means for us is, no matter how much care I put into expertly fitting our doors to within exact tolerances, the foundation will eventually shift one way or another and the door either won’t close or won’t stay closed. The pantry door, however,was another story. It had it out for me.

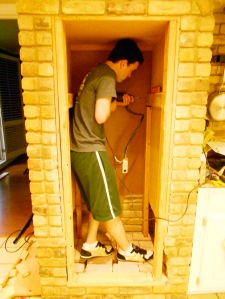

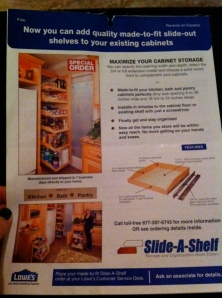

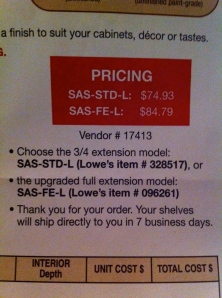

Julie was convinced we needed a door that matched all the other interior doors we were installing in the house. The pantry opening was 20″ and the smallest door I could find (without custom ordering something for like a million dollars or whatever) was 24.” “No worries,” I foolishly thought, “I’ll just cut 2″ off each side.” I was in for a bit of a surprise.

As I began cutting into the door I learned something very disheartening: doors are now such low-quality crap that they’re hollow. As in, there’s nothing between the side you open and the side you close. It’s just air. Now, I’m all about cutting costs, building efficiently, and conserving materials, but when my door is barely as sturdy as the box it came in, it tends toward the ridiculous. I’m kind of scared to knock.

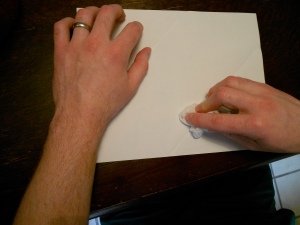

Look at this junk:

So what did I do? Well,I had three options: order a custom door (I’d have to take out a second mortgage), buy a second door and try to figure something else out (I already wasted money on this one, why would I buy another useless cardboard box?), or do what I do best and pinch my pennies until a solution falls out. So, I took the one solid piece of the door (i.e. the outer frame, which is probably only there so you can mount hinges) and hammered it back in to make my own custom-sized door.

After a little glue, wood filler, and frustration, I had my own custom door. Is this the most ghetto thing I’ve ever done? Yes. Did it work? Mostly. It was still a tight squeeze so I had to sand it down in a few places.

Once I got it mounted and installed the knob, I had a door that was about 80% functional and, most importantly, looked good closed. For now.

As it turns out, the thin frame I reinstalled wasn’t quite up to the job of being, what I now realize, the most frequently operated door in the house, not to mention the fact it had a spice rack bolted to the back. Eventually the screws for the hinge managed to work themselves loose and a few had even ripped themselves out. So, effectively, the door fell off. Oops.

Hers.

Well, that didn’t go exactly as planned. It wasn’t all lost though. I took this as an opportunity to sneak in more “shabbiness” to our home (shh don’t tell Chris- he thinks shabby translates to junk, ha). Besides, I had been dreaming of an old rustic-looking pantry door anyway. None of that standard builder grade stuff here!

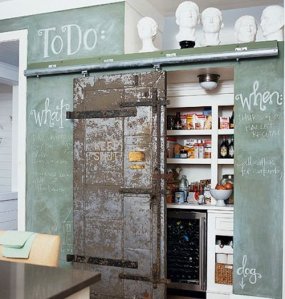

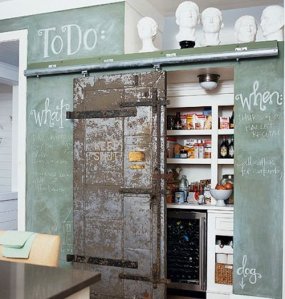

Come join me in my drool-fest over these fantasticly shabby doors:

Source: Houzz via Pinterest

Source: Two Maisons

Source: Down to Earth Style

Source: Cottage Living

So, here’s the part where I tell you I found the perfect shabby contender for our pantry door, right? Right. Here you go. Just look at her.

She was p-e-r-f-e-c-t. And the best part? I found her at a local architectural salvage place so, of course, she cost next to nothing for me to claim her. Like $1o nothing. Done and done. Right?

Wrong.

Sooomeone (*ahem Chris) had to rain on my parade with the ole “I bet it’s lead paint” line. Sigh, how I hate when the hubby proves me wrong. Lead paint… pantry…. food… it doesn’t make for the best combo. And now we mourn. Goodbye old, poison-infused door.

Sooo we were nowhere closer to keeping Chloe the cat out of turning our pantry into her personal jungle gym aka finding a pantry door.

To cheer me up, Chris drove us over to a second architectural salvage shop. I kid you not, I sorted through the door section (which is made up of 400 or so doors) a full three times before I finally gave up and admitted they didn’t have anything that would fit the bill. Not only that, but this place was significantly more expensive, like $60-100 per door more expensive. I may be a little naive but isn’t paying $100 for an old beat-up door a little ridiculous, even for me?

As I made my way to the exit (moping and dragging my feet in disappointment of course), I saw an excited Chris galloping towards me. I figured he found some old tools or, worse, the expensive set of gas logs he’s tried to talk me into for the last seven visits (what’s wrong with good ole firewood??). But, instead, he claims to have found the perfect door… in the shutter room. Whaa?

We rounded the corner to find piles upon piles of old house shutters stacked against each other. It’s like the TJ Maxx of shutters in there. Ugh, and I hate sorting.

I decided to forfeit one clean finger to gingerly push each shutter from the other, one by one until I finally found the perfect candidate.

BOOM.

Helloooo new door. What was most funny about this find was that finding a door for our oddly shaped pantry opening (20″ wide) had been a nightmare. Door manufacturers apparently didn’t go that skinny. This shutter was the perfect width! All we had to do was trim it down a little on the bottom, which was solid wood so we wouldn’t have the problem we had with the last door which was hollow. Also, it had all that intricate molding that made those old shabby doors look dull in comparison. I was even sold on the black paint. Glossy black doors ARE all the rage now, afterall. Why not jump on that bandwagon already?

It was originally listed for $60 but, because it was a lone soldier- all the other matching shutters were either gone or didn’t make it to the store, the store discounted it down to $30 for us. Why, yes, we will pay an additional $20 for a few extra years on our life aka a lead paint-free door.

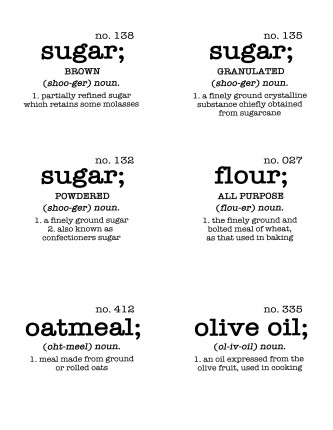

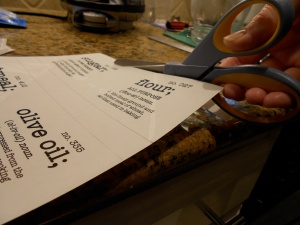

At this point, I was on a roll. As we walked up to the counter to pay, we passed by the door accessories room (this salvage shop is so magical). The heavens parted and there was my antique door plate and antique crystal knob that would complete the look of our pantry door. Mama needs some bling, mk?

A $5 door plate, $7 knob, and $30 door later, we were all set. There was no stopping us now!

His.

Alright, so we had to scrap the original door idea and were back to square one. By now Julie had decided that she really wanted an antique door, and since door dimensions weren’t really standardized until later in the 20th century, I figured that might not be a bad route to take. If nothing else, older doors are probably solid wood and can be cut to size without any, um, issues. So it was off to the “architectural salvage warehouse,” i.e. overpriced junkyard.

Our first stop was in a part of town that’s… well, it was in the hood. Like, I was surprised no one pulled smash n’ grab for my car radio. Anyway, they had just about every door ever installed in Dallas before 1950, so there was plenty to choose from. One common factor, though, was that they all had the tell-tale signs of lead paint. I don’t possess the equipment, facilities, or expertise to properly remove and dispose of lead paint, and since my health insurance provider and I would prefer to avoid permanent nervous system damage I told Julie there was no way we were getting any of those doors. Sorry ’bout your bad luck…

Now, at this point Julie and I were getting into a fairly expressive argument over how I wanted her to be miserable the rest of her life by choosing my nervous system over her door, and an employee came over to see what all the fuss was about. Julie explained how much she loved toxic doors and I explained how much I love not dying, and the woman did her best to quell my fears. “Oh, you have nothing to worry about,” she said reassuringly, “I’ve been around this stuff for two whole years and I’m fine!” At that moment we both noticed that her hair probably hadn’t been washed since 1997 and she spoke through what can only be described as “meth teeth”… and we began looking for the exit.

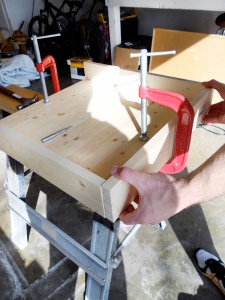

Anyway, Julie has already told a mostly accurate story of how we found our actual door, so I’ll skip forward to what we ended up doing with it. It was in pretty sad shape when we got it and definitely needed to be cleaned up and painted, but overall the wood was in good condition except at the very bottom (this is a shot of the back side, which was never painted since it faced the side of a house in its former life as a shutter):

Once we got it cleaned up and scraped off any stray splinters, we painted it an oil-based flat black. I really hate working with oil-based paint, but they really do lay down the best finishes.

True to form, Julie’s original color choice didn’t last long, and a day later she decided it looked too much like a chalkboard. So I went out to buy some gloss black.

Once it was painted, I had to cut it down to size. Remember the bit at the bottom I said was in sad shape? Well, as luck would have it, that’s exactly how much I needed to chop off!

The final challenge was finding a latch. We were able to re-use the hinges from the old door, but the molding and accents on the door made it just impossible enough to fit a traditional latch that we were once again scratching our heads. My brilliant solution? A ball catch, typically seen mounted on the frame of a door that presses closed. This basically made our knob a dummy knob, which meant it could be mounted anywhere we wanted.

After.

His.

“It’s like, how much more black could this be? And the answer is, none. None more black.”

Pop quiz- what movie is this from?